As an Amazon Associate I earn from qualifying purchases.

Greetings from the exciting world of 3D printing. where innovation knows no bounds. As the demand for customization and rapid prototyping continues to soar, 3D printing has established itself as a revolutionary force across diverse industries. From manufacturing to healthcare and beyond, the allure of transforming digital designs into tangible objects has captured the imagination of creators worldwide.

The growing popularity of 3D printing isn’t merely a trend; it’s a transformative wave reshaping the way we approach production and design. Industries that once relied solely on traditional manufacturing processes are now integrating 3D printing technologies to enhance efficiency and unlock new possibilities. As this technology becomes increasingly accessible, the question arises: How much does it truly cost to run a 3D printer?

In this blog post, we embark on a journey to unravel the intricacies of 3D printing costs. Beyond the awe-inspiring capabilities of this cutting-edge technology lies a practical consideration—the financial aspect. Understanding the costs associated with running a 3D printer is crucial for businesses, hobbyists, and enthusiasts alike. Join us as we explore the economics of this game-changing technology, whether you’re new to 3D printing or want to optimize your current setup.

Let’s demystify the expenses, explore essential factors, and gain insights into managing the cost landscape of 3D printing. Get ready to navigate the exciting intersection of creativity and finance in the world of 3D printing.

Initial Investment Costs

We’re diving headfirst into the financial side of the 3D printing universe. Buckle up because we’re breaking down the Initial Investment Costs that come with embarking on your 3D printing journey.

A. Cost of the 3D Printer

Let’s talk about the heart of your 3D printing setup—the printer itself. Now, you’ve got choices, my friend. On one hand, you’ve got the entry-level printers, the friendly neighborhood spide… I mean, printers that are perfect for beginners. They won’t break the bank, and they’re a fantastic way to dip your toes into the 3D printing pool. On the other hand, we’ve got the heavy hitters—the professional-grade printers. These bad boys promise excellent quality and speed and come with all the bells and whistles, promising top-notch quality and speed. Your choice here will set the tone for your 3D printing adventure, so choose wisely.

1. Entry-level vs. Professional-grade Printers

Entry-level printers: Affordable, beginner-friendly, and great for getting started.

Professional-grade printers: High-end, faster, and packed with advanced features for the pros.

2. Consideration of Brand and Features

Every brand brings its own flavor to the table. Do your homework—check reviews, compare features, and find a brand that suits your needs. Don’t forget to look for user-friendly features that align with your skill level.

B. Essential Accessories and Tools

Now, let’s deck out your 3D printing space with the essential accessories and tools. Think of these as the sidekicks to your 3D printer superhero.

1. Filaments

Filaments are your printing materials, and they come in various types and colors. PLA, ABS, PETG—each has its strengths. Think about the intended use of your prints and select your filament wisely. Keep an eye out for budget-friendly options without compromising quality.

2. Print Bed Materials

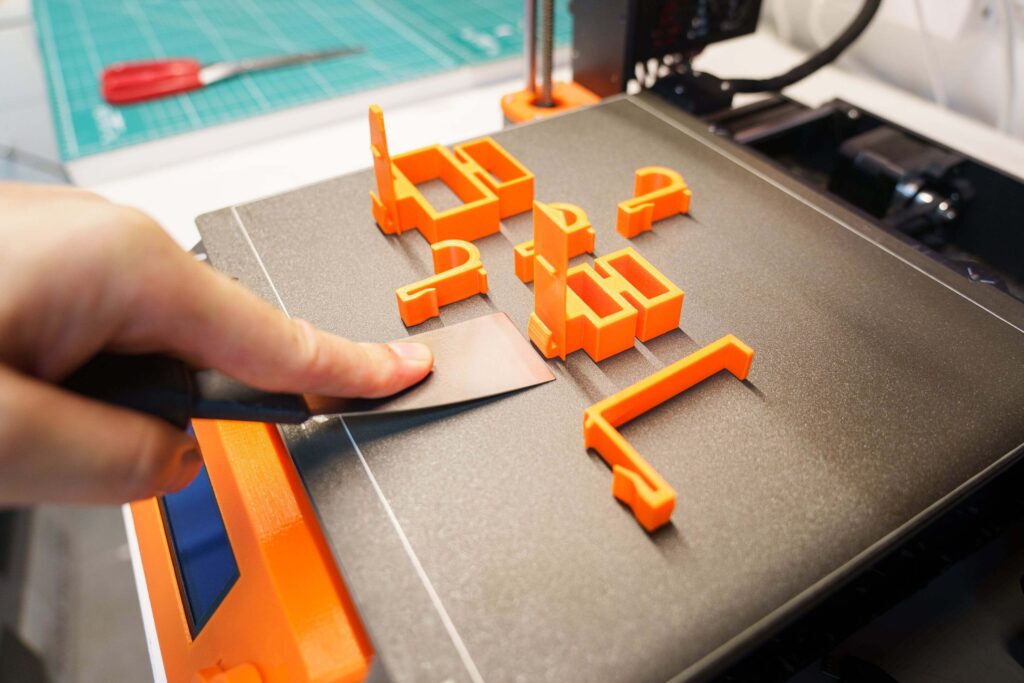

Your prints need a cozy spot to take shape, and that’s where print bed materials come in. Glass, magnetic, or specialized surfaces—pick what suits your needs. A smooth bed surface ensures your creations pop off easily.

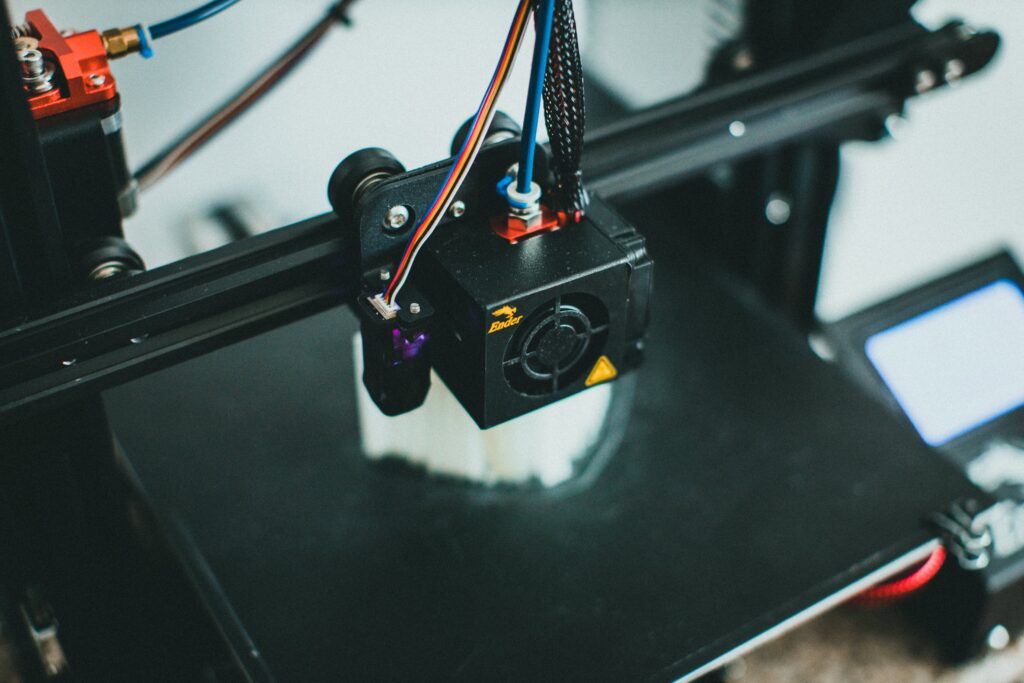

3. Nozzles and Extruders

These are like the wizards of your 3D printing realm. Nozzles control the flow, and extruders push out the magic—your filament. Invest in quality nozzles and extruders to avoid hiccups in your printing adventures.

Remember, finding the right balance between cost and quality is the key to a successful 3D printing setup.

Operational Costs: Navigating the Power Surge

A. Energy Consumption

1. Power Usage of 3D Printers

It’s important to take your printer’s energy consumption into account before venturing into the realm of 3D printing. Different models come with varying power requirements, and understanding this can save you from unpleasant surprises. Larger, industrial-grade printers may demand more electricity, impacting both your usage patterns and, inevitably, your monthly bills.

2. Impact on Electricity Bills

Let’s be real—while crafting intricate designs layer by layer is awe-inspiring, it’s not without its consequences on your utility expenses. We’ll unravel the intricacies of how 3D printing impacts your electricity bills and explore strategies to keep both your creations and costs under control.

B. Maintenance and Repairs

1. Regular Maintenance Tasks

Just like any mechanical marvel, 3D printers thrive on regular TLC (tender loving care). We’ll walk you through the essential maintenance tasks that keep your printer humming smoothly. From nozzle cleaning rituals to bed leveling practices, these preventive measures ensure your printer stays in peak condition, minimizing unexpected hiccups.

2. Potential Repair Costs

Despite our best efforts, printers can throw a wrench in the creative process with unexpected malfunctions. We’ll discuss the potential repair costs, providing insights into troubleshooting common issues and assessing when it’s time to call in the professionals. Being prepared for these contingencies ensures your 3D printing journey is a marathon, not a sprint.

C. Software and Design Tools

1. Cost of 3D Modeling Software

In the digital realm, creating a blueprint for your physical masterpiece often involves investing in 3D modeling software. We’ll explore the cost landscape of popular tools, discussing both free and premium options. Whether you’re a seasoned designer or a beginner taking your first steps, we’ll guide you through choosing the right software for your needs.

2. Additional Tools for Design Optimization

Beyond the basic software, certain additional tools can elevate your design game. From mesh repair utilities to slicer software, these optimization tools play a crucial role in refining your creations. We’ll shed light on their functionalities, costs, and how they contribute to the overall efficiency of your 3D printing endeavors.

Material Costs

Let’s dive deep into the heart of 3D printing—material costs. As we embark on this journey, I’ll be your guide through the labyrinth of filament choices, costs, and the art of optimizing material usage for your 3D printing adventures.

A. Types of Filaments: Unveiling the Palette of Possibilities

Filaments are the brushstrokes that, in 3D printing, give your creations life.

Understanding the nuances of each filament type is crucial for achieving the desired results.

1. PLA, ABS, PETG, etc.: PLA, the eco-friendly sweetheart; ABS, the robust workhorse; PETG, the perfect blend of strength and flexibility—these are just a few members of the filament family. Each type boasts its unique characteristics, influencing factors such as print quality, durability, and suitability for specific applications.

2. Specialty Filaments and Their Costs: Elevate your prints with specialty filaments designed for specific purposes. Whether it’s wood-infused filaments for a natural finish or conductive filaments for functional electronic parts, these specialty options bring a touch of magic to your creations. However, such enchantment often comes with a higher price tag—something we’ll explore in detail.

B. Calculating Material Usage: Unraveling the Mystery

Now that you’ve chosen your filament palette, let’s demystify the art of calculating material usage, ensuring every spool contributes to a masterpiece.

1. Understanding Filament Consumption: Filament isn’t an infinite resource, and understanding its consumption is key to managing costs. Factors such as layer height, infill density, and print speed influence how much filament your 3D printer devours per project. We’ll uncover the secrets to optimizing these variables for efficiency without compromising quality.

2. Cost per Print: In the world of 3D printing, knowledge is power, and that includes knowing the financial impact of each print. We’ll break down the cost per print, considering not just the filament but also the energy consumed and wear on your printer. Equipped with this understanding, you may decide on your initiatives wisely, striking a balance between originality and economy.

Hidden Costs

In the mesmerizing realm of 3D printing, where dreams are transformed into tangible realities, there exists a subtle dance with hidden costs. Beyond the initial investment and apparent operational expenses lies a labyrinth of financial nuances that can significantly impact your journey. Today, we shine a spotlight on two clandestine culprits that might be stealthily affecting your budget: failed prints and material wastage, as well as the ever-tempting realm of upgrades and enhancements.

A. Failed Prints and Material Wastage

1. Impact on Overall Costs

One of the silent saboteurs to your 3D printing budget is the tale of failed prints and the accompanying material wastage. Every unsuccessful attempt not only consumes valuable time but also translates into wasted resources. The cost of these failed prints extends beyond the immediate loss of materials—it includes energy consumption, wear and tear on your 3D printer components, and, perhaps most significantly, the impact on your overall printing efficiency.

2. Tips to Minimize Wastage

Fear not, for there are strategies to minimize this hidden cost. Calibration is key; ensuring your 3D printer is finely tuned reduces the likelihood of failed prints. Additionally, utilizing software features like support structures and brims can enhance print success rates. By adopting meticulous design practices and optimizing print settings, you’ll not only save on materials but also contribute to a more sustainable and cost-effective 3D printing process.

B. Upgrades and Enhancements

1. Investing in Better Components

The allure of enhancing your 3D printer’s capabilities is undeniable. Upgrading components such as nozzles, extruders, or even the entire printing bed can promise improved performance, finer details, and quicker prints. However, the costs associated with these upgrades can accumulate swiftly.

2. Evaluating the Necessity of Upgrades

Before succumbing to the siren call of upgrades, critically evaluate the necessity of each enhancement. Take into account the particular requirements of your initiatives and balance the expenses and possible rewards. Sometimes, incremental upgrades may offer a more cost-effective solution than a complete overhaul.

In the intricate tapestry of 3D printing costs, these hidden factors demand attention. By acknowledging and strategizing around failed prints, material wastage, and prudent upgrade decisions, you empower yourself to navigate the financial landscape of 3D printing with confidence. Stay tuned as we unravel more secrets to optimizing your 3D printing expenses. The journey to mastery continues!

Tips for Cost Optimization

In the dynamic realm of 3D printing, finding the perfect balance between creativity and cost-effectiveness is an art form. As a seasoned blog writer, I’ve witnessed firsthand the excitement and challenges that come with exploring the limitless possibilities of this transformative technology. In this post, let’s dive into the realm of Tips for Cost Optimization, uncovering practical strategies to make your 3D printing journey not only efficient but also budget-friendly.

A. Choosing Cost-Effective Materials

Selecting the right materials can significantly impact your 3D printing expenses. Even if there are many alternatives available, it’s crucial to balance cost and quality. Consider exploring cost-effective filaments like PLA (Polylactic Acid) and PETG (Polyethylene Terephthalate Glycol) for everyday projects. For specialized applications, weigh the benefits of higher-end materials against their price tags. In doing so, You’ll guarantee that every print produces the anticipated outcomes without going over budget.

B. Energy-Saving Strategies

The cost of energy can add up over time, especially for avid 3D printing enthusiasts. Implementing energy-saving strategies not only contributes to a greener footprint but also trims down your electricity bills. Optimize print settings to reduce print times, invest in energy-efficient 3D printers, and explore scheduling prints during off-peak hours. These subtle adjustments can make a notable difference, allowing you to pursue your creative endeavors without worrying about inflated utility costs.

C. Preventive Maintenance to Avoid Major Repairs

A stitch in time saves nine, and the same principle applies to 3D printing. Regular preventive maintenance can prevent minor issues from snowballing into major repairs, saving you both time and money. Clean and lubricate moving parts, regularly check the calibration, and keep an eye on the wear and tear of components. By adopting a proactive approach to maintenance, you’ll not only extend the lifespan of your 3D printer but also minimize the likelihood of costly repairs down the line.

D. Utilizing Open-Source Software for Design

In the world of 3D design, open-source software emerges as a cost-effective and powerful ally. Open-source programs like Blender, FreeCAD, and TinkerCAD provide robust features without the hefty price tags associated with some proprietary design software. Embracing these tools not only reduces upfront costs but also fosters a collaborative and supportive community. Use the community’s pooled knowledge and experience to improve your ideas without going over budget.

In conclusion, mastering the art of 3D printing involves more than just pushing the boundaries of creativity—it’s about optimizing costs intelligently. By carefully choosing materials, implementing energy-saving practices, prioritizing preventive maintenance, and utilizing open-source software, you’ll not only refine your 3D printing skills but also ensure that your passion for creating remains financially sustainable.

Estimated Cost (In Numbers)

Numerous factors might cause a 3D printer’s operating costs to fluctuate significantly, including the type of 3D printer, the materials used, the frequency of use, and the specific printing requirements. Here’s a rough estimate to provide a general idea:

Initial Investment:

– 3D Printer: Entry-level models can start at around $200, while professional-grade printers can range from $500 to several thousand dollars.

– Accessories: Additional tools, filaments, and accessories may cost anywhere from $50 to a few hundred dollars.

Operational Costs:

– Energy Consumption: The energy cost to run a 3D printer per hour is relatively low, typically ranging from $0.10 to $0.50.

– Maintenance: Regular maintenance costs are minimal but can include occasional replacement parts, which might range from $20 to $100 annually.

Material Costs:

– Filaments: The cost of filaments varies based on the type (PLA, ABS, PETG, etc.) and brand. On average, expect to spend $20 to $50 per kilogram of filament.

Hidden Costs:

– Failed Prints and Wastage: Depending on the complexity of prints and the learning curve, factor in a potential 10-20% wastage, which can add to material costs.

Software and Design Tools:

– 3D Modeling Software: Some software is free, while professional tools may have subscription costs ranging from $10 to $50 per month.

Overall Estimated Annual Cost:

Considering these factors, the average annual cost to run a 3D printer for a hobbyist might be in the range of $300 to $800. For businesses or professionals with higher usage and more advanced equipment, costs can scale accordingly, potentially reaching several thousand dollars.

It’s important to remember that these are only approximate charges and that actual expenses may differ depending on specific situations. Regular maintenance, careful material usage, and energy-efficient practices can help optimize and minimize these costs over time.

FAQs

Ah, the perennial question! A 3D printer may be purchased for a broad range of prices; it’s similar to selecting a smartphone with customized features. Entry-level models for hobbyists can be found for a few hundred dollars, while professional-grade machines boasting cutting-edge features may command a steeper investment. Remember, the right printer for you depends on your intended use and budget

Navigating the vast array of filament options can be overwhelming. For those taking their first steps in 3D printing, I recommend starting with PLA (Polylactic Acid). It’s user-friendly, boasts a low melting point, and is environmentally friendly. As you gain experience, you can explore other materials like ABS and PETG for diverse applications.

While 3D printing is incredibly versatile, there are design considerations. It’s important to grasp design principles since not all designs are appropriate for 3D printing. Complex geometries and intricate details may require advanced skills and support structures. However, with the right software and a bit of practice, the possibilities are nearly limitless.

Like any technology, the lifespan of a 3D printer depends on factors such as usage, maintenance, and quality. Entry-level printers may last a few years with regular care, while high-end models can endure for a decade or more. Regular maintenance, timely upgrades, and responsible use contribute to extending the lifespan of your 3D printer.

Ah, the budget-conscious creator’s query! To optimize costs, consider factors like material usage, energy efficiency, and smart purchasing decisions. Experiment with open-source software for design, explore cost-effective filaments, and practice good print bed optimization to minimize material wastage.

conclusion

In the grand symphony of innovation, where every filament extrusion and layer deposition contributes to the creation of something extraordinary, we find ourselves at the conclusion of our exploration into the financial landscape of 3D printing.

Summarizing Key Points:

Throughout this journey, we’ve dissected the cost anatomy of 3D printing, examining the initial investment, operational expenses, material costs, and those often overlooked hidden expenditures. From choosing the right printer to optimizing material usage, we’ve covered it all. The dance of dollars and cents within the realm of 3D printing may seem intricate, but fret not; clarity emerges as we distill these complexities into digestible insights.

Emphasizing the Importance of Understanding and Managing Costs:

Now, as we stand at the crossroads of creativity and fiscal responsibility, it’s imperative to underscore the profound importance of comprehending and managing the costs associated with 3D printing. Beyond the sheer thrill of bringing digital designs to life, there exists a pragmatic consideration—one that can make or break endeavors.

Imagine having the power to predict and control your 3D printing expenses, ensuring that your creative pursuits align harmoniously with your budgetary constraints. This isn’t just financial wizardry; it’s a strategic approach to amplify the ROI of your 3D printing ventures.

In a world where innovation races alongside economic prudence, mastering the art of cost management becomes a skill as valuable as the designs you bring to fruition. The path continues beyond the last layer of your print, regardless of your level of experience; it encompasses sustained creativity, attentive money management, and wise decision-making.

As we bid adieu to this exploration, let the echoes of fiscal wisdom resonate in your future 3D printing endeavours. May your prints be precise, your designs be visionary, and your costs be under control. Here’s to the boundless possibilities that unfold when creativity meets financial acumen in the captivating world of 3D printing!

Related Guide

What Things You Can Make with a 3D Printer to Sell?

How to Make Money with a 3D Printer

Amazon and the Amazon logo are trademarks of Amazon.com, Inc, or its affiliates.

Leave a Reply